The 2408i provides you with accurate indication and alarming of temperature and process measurements. Process interlocks, including over temperature furnace limits, are implemented using relay outputs.

Now enhanced for cyber-security robustness

The 2704 Advanced Controller is a highly accurate and stable process controller available in a single, dual or triple loop format. Features include setpoint programming and a comprehensive selection of math and logic functions.

2704 Advanced Controller

Description

- High performance measurement – the best in class control

- Flexible I/O – meets many diverse requirements

- Feature rich – more than just a temperature controller

- Application specific functions – simplifying complex applications

- Graphical soft wiring – easy to be creative and find solutions to complex problems

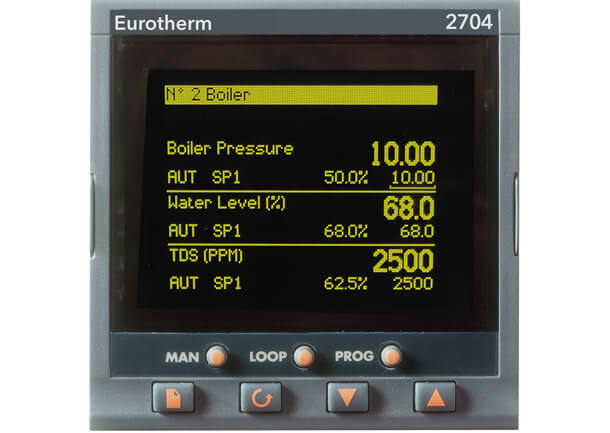

Its user interface incorporates a bright dot matrix display, providing extreme flexibility and ease of use. It is a highly configurable product offering many features previously only found in programmable logic controllers (PLC). This enables systems to be implemented integrating the process control and logic functions of a machine – simplifying system complexity and reducing total system costs.

Configuration is achieved either via the front panel interface of using the iTools configuration software.

High Precision Process Input

If you cannot measure accurately, you cannot control accurately. The 2704 offers typical resolution of 0.25uV making it ideal for applications such as semiconductor, vacuum heat treatment and research applications. All thermocouple input types are catered for, as are Pt100 resistance thermometers and linear input types such as 0-10Vdc and 4-20mA. Four wire Pt100, and Pt25 measurement is also possible using a module specially designed for high accuracy metrology applications.

The 2000IO expander can increase the digital I/O providing the option for greater remote operation of the programmer and expanding the 2704 logic capability:

- 20 logic inputs

- 20 relay outputs

Setpoint Programmer

- Ideal for atmosphere or vacuum furnaces and environmental chambers

- 60 programs

- 3 profiled setpoints/program

- 600 segments

- 16 event outputs

- program mimic display

60 setpoint programs, each with 16 digital events can be stored. A total of up to 600 segments can be programmed, and holdback, wait functions and digital inputs offer an extremely flexible solution for applications such as carburizing and vacuum furnaces, environmental chambers and autoclaves.

Digital communications

- Modbus RTU

- Ethernet Modbus/TCP

- Profibus DP

- Devicenet® network communications

- EI-Bisync

- Master Modbus

The 2704 Advanced Controller supports two slave communication ports. Its modular build provides the user with a selection of communication protocols enabling easy integration into both PLC and PC supervisory systems.

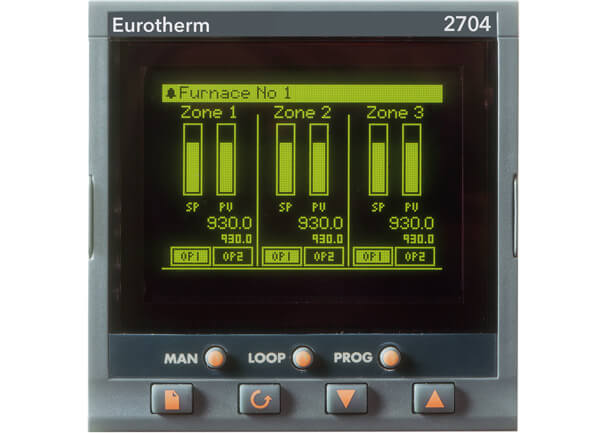

Master Modbus communications significantly increase the applications open to the 2704 Advanced Controller. In its simplest form it can be used to retransmit a setpoint to a number of slave controllers in a multi-zone furnace. Alternatively it can be integrated with the Mini8 16 loop controller to provide a remote operator interface with setpoint programmer functions.

Description

- High performance measurement – the best in class control

- Flexible I/O – meets many diverse requirements

- Feature rich – more than just a temperature controller

- Application specific functions – simplifying complex applications

- Graphical soft wiring – easy to be creative and find solutions to complex problems

Its user interface incorporates a bright dot matrix display, providing extreme flexibility and ease of use. It is a highly configurable product offering many features previously only found in programmable logic controllers (PLC). This enables systems to be implemented integrating the process control and logic functions of a machine – simplifying system complexity and reducing total system costs.

Configuration is achieved either via the front panel interface of using the iTools configuration software.

High Precision Process Input

If you cannot measure accurately, you cannot control accurately. The 2704 offers typical resolution of 0.25uV making it ideal for applications such as semiconductor, vacuum heat treatment and research applications. All thermocouple input types are catered for, as are Pt100 resistance thermometers and linear input types such as 0-10Vdc and 4-20mA. Four wire Pt100, and Pt25 measurement is also possible using a module specially designed for high accuracy metrology applications.

The 2000IO expander can increase the digital I/O providing the option for greater remote operation of the programmer and expanding the 2704 logic capability:

- 20 logic inputs

- 20 relay outputs

Setpoint Programmer

- Ideal for atmosphere or vacuum furnaces and environmental chambers

- 60 programs

- 3 profiled setpoints/program

- 600 segments

- 16 event outputs

- program mimic display

60 setpoint programs, each with 16 digital events can be stored. A total of up to 600 segments can be programmed, and holdback, wait functions and digital inputs offer an extremely flexible solution for applications such as carburizing and vacuum furnaces, environmental chambers and autoclaves.

Digital communications

- Modbus RTU

- Ethernet Modbus/TCP

- Profibus DP

- Devicenet® network communications

- EI-Bisync

- Master Modbus

The 2704 supports two slave communication ports. Its modular build provides the user with a selection of communication protocols enabling easy integration into both PLC and PC supervisory systems.

Master Modbus communications significantly increase the applications open to the 2704. In its simplest form it can be used to retransmit a setpoint to a number of slave controllers in a multi-zone furnace. Alternatively it can be integrated with the Mini8 16 loop controller to provide a remote operator interface with setpoint programmer functions.

| Analogue IP/OP In | 8 |

| Analogue IP/OP Out | 8 |

| Combinational Logic | 32 Operations |

| Control Algorithms | User wired, Cascade, Override, Single |

| Control loops | 3 |

| Digital Comms | DeviceNet, Ethernet, Modbus, Profibus |

| Digital IP/OP In | 44 |

| Digital IP/OP Out | 43 |

| Maths Equation | 32 Calculations |

| PC Configuration | Graphical wiring |

| Special Features | Vacuum, Carbon Potential, Humidity, Melt Pressure |

| Timers/Counters/Totals | 4 / 0 / 4 |

| Panel size (DIN) | 1/4 |

| Input Type | mA, mV, RTD, TC, Volts |

| PV Accuracy | <0.1% |

| IP Rating | IP65 |

| Display Type | Dot Matrix |

| Control Types | On/Off, PID, VP |

| Alarm Types | Dev, Event, Heater fail, Hi, Lo |

| Supply Voltage | 24V dc/ac, 85-264V ac |

| SP Programmer | 60 Programmes, 600 Segments max |

| Real Time Clock | Day and Time |